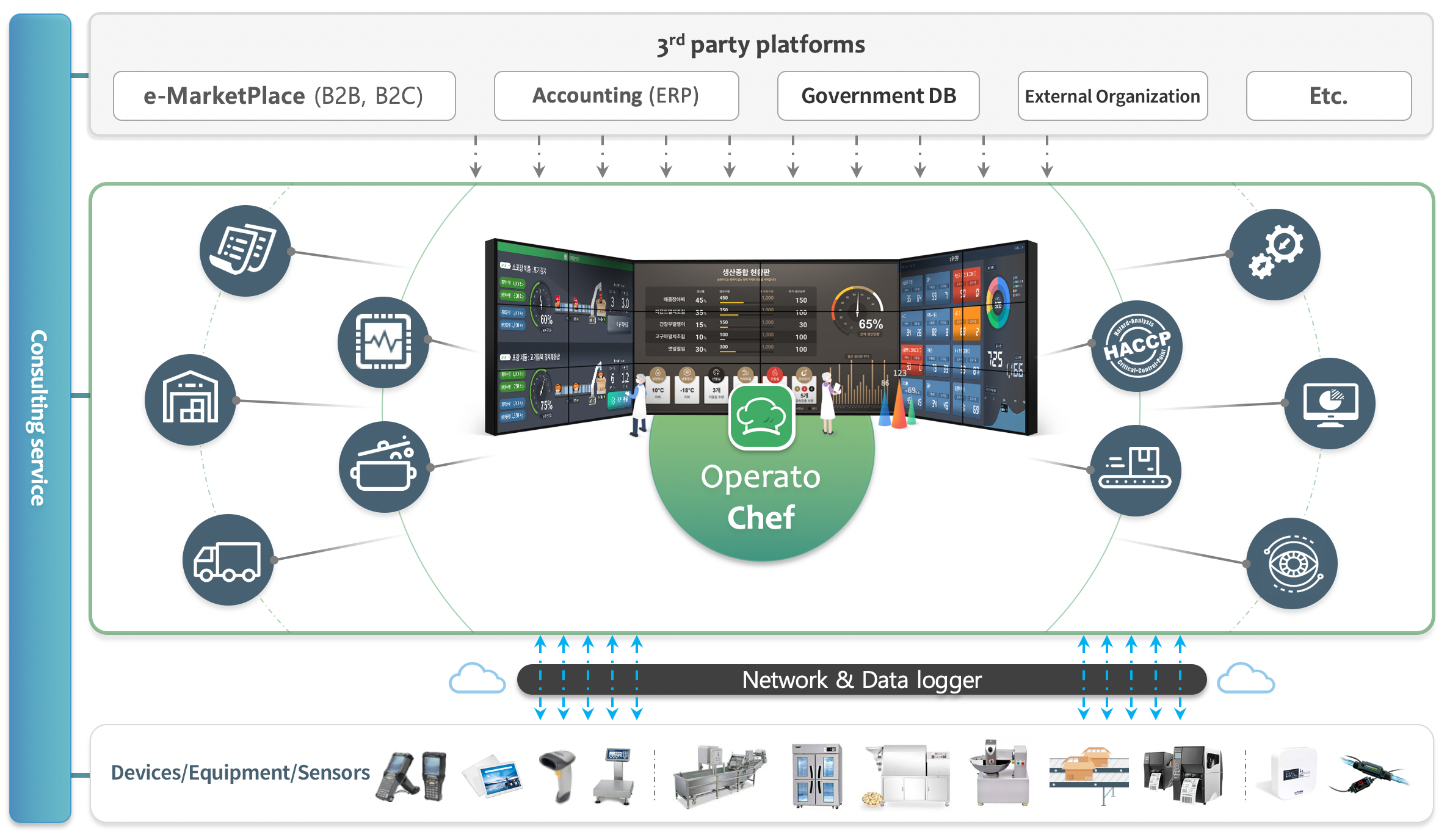

Operato Chefprovides optimized smart factory solutions tailored to customer needs, enhancing production efficiency and competitiveness.

From customer order management to optimized production operations focused on food manufacturing, the Operato Platform offers a variety of modules tailored to customer needs, including user convenience and shipment vehicle management.

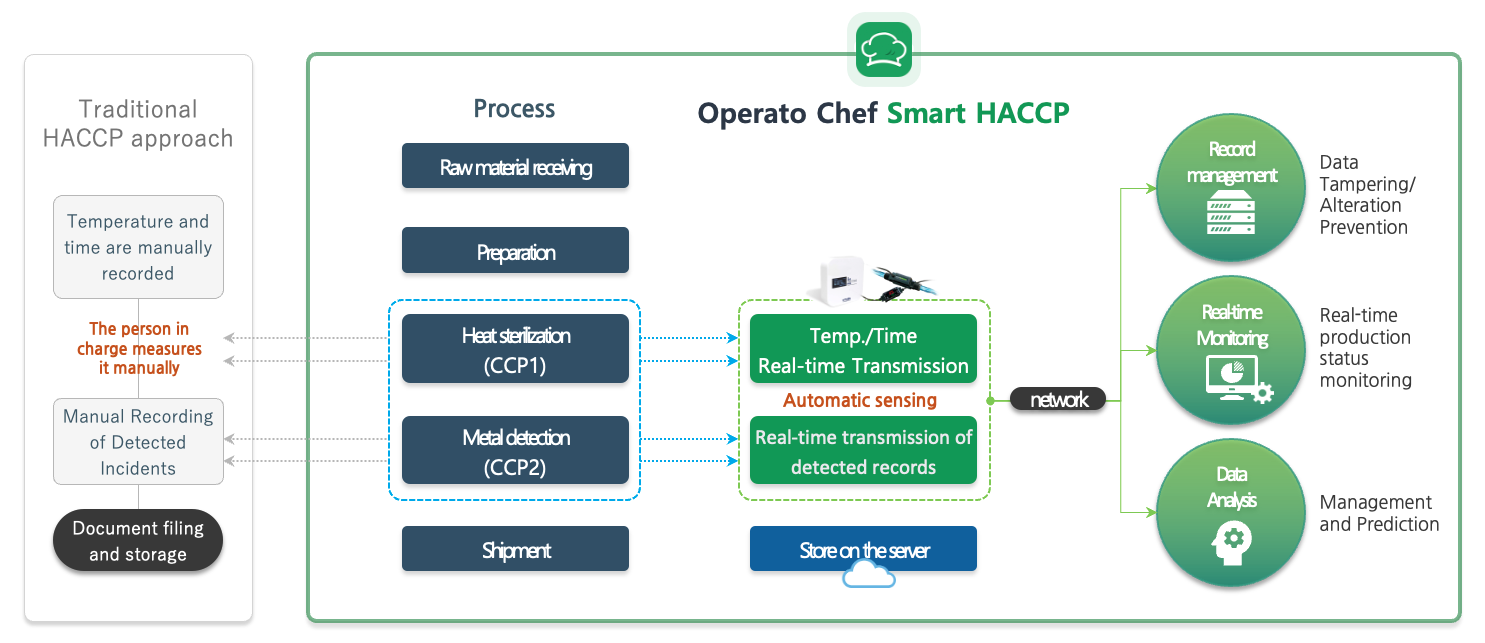

We automatically collect data on the food production environment and processes, and analyze the collected data. This includes incorporating workflows for managing deviations from limits, thereby simultaneously offering the construction and certification of Smart HACCP systems.

We provide a range of smart devices suitable for on-site equipment, workflows, and environments, from smart scales for automated yield management to various sensors and devices that easily collect data from different facilities and environmental data.

One stop shopping for Smart Factory

A Smart Factory is not just made up of IoT devices.

From connecting existing equipment to the network to various

sensors and smart scales, similar IoT devices, and building a

network infrastructure for stable data transmission, Operato Chef

enables One Stop Shopping, encompassing software for food

production and operational management.

Just as each company has different goals and situations,

Smart Factories should also be different.

Especially when the products produced and the markets

are different, this is even more the case.

Operato Chef provides services to design systems

that align with the diverse goals and situations of food

and beverage manufacturing clients.

- Situation Analysis and Business Goal Setting: Comprehensive analysis of sales, procurement, production, shipping, delivery, etc., establishing objectives for Smart Factory construction, deriving KPIs, etc.

- Process Improvement and System Configuration Plan: Identifying bottlenecks/improvement points, establishing system configuration based on process improvement strategies.

- Data Collection Strategy: Creating a list of necessary data such as CCP, quality, process, production, inventory, etc., and establishing a data collection plan suitable for the site.

- User Interface Design: Configuring user interfaces suitable for specific processes, roles, and positions, and preventing work errors through intuitive screen layouts.

Data collection is a very important first step in

configuring a Smart Factory.

Along with stable data collection, we

carefully select equipment suitable for the

production site to provide to our customers.

- Sensors: Temperature/humidity sensors, flow sensors, current sensors, vibration sensors (for equipment maintenance), temperature sensors for vehicles, etc.

- Data Collection: Barcode scanners, smart scales

- Tablets: Receiving and entering work orders through screens suitable for each site

- Label Printer: Label management software (Operato Chef) and industrial label printers

With the increasing automation equipment, operations can

now be conveniently managed.

We build a system that

connects automated equipment installed on-site, various

measurement and detection devices, PLCs, etc., to

collect, monitor, and analyze centrally.

- Network: Designing/building wired/wireless networks, supplying/configuring network security equipment such as firewalls, etc.

- Data Collection: Gateways for transmitting data from PLCs, various control panels, sensors to servers, data loggers, etc.

Operato Chef is the heart of the Food and Beverage

Smart Factory.

Using collected data to understand each process's

status, from customer orders to shipment vehicles,

Operato Chef provides various functions suitable for

food and beverage manufacturing companies.

- Smart HACCP and Quality Management

- Production/Process Management, Warehouse/Inventory Management, Shipment Management

- Defect Tracking and Root Cause Analysis

- Understanding Management Indicators such as Production, Inventory, Shipment, and Process Status

What is Smart HACCP?

Smart HACCP is a comprehensive quality management system that

manages Critical Control Point (CCP) monitoring data in the food

manufacturing process using IoT technology.

It digitalizes

technical logs and quality-related data, allowing for real-time

automatic recording, management, verification, and storage.

This

prevents data tampering and facilitates analysis and usage,

extending to production management and inventory in/out

management.