Make Decisions Easily, Work Comfortably with Operato Chef

From order management to inventory tracking, production planning, and work orders, to shipment and delivery, everything can be managed at a glance and monitored in real time.

Just like topping a salad,

just choose the features you need, and you're OK!

The key to food and beverage manufacturing is data! From product

to the know-how data of sauce mixing, operato-chef is the go-to

for managing quality data for each manufacturing process.

It securely manages essential know-how data, and perfectly

handles the automatic collection, analysis, monitoring, and

prediction of quality data for each manufacturing process.

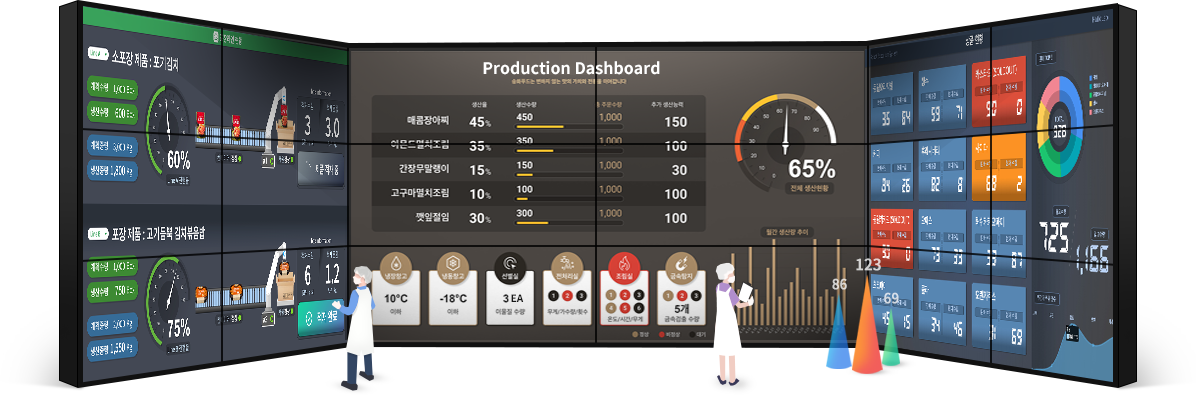

Automatically collects crucial data across manufacturing, including HACCP data, process/production, inventory, etc., and transmits it to the cloud in real-time.

Analyzes various data collected in the cloud to automatically create CCP check logs, and transmits production/process/inventory data analysis to monitoring dashboards.

Real-time monitoring of management indicators and key control items, with alerts for deviations, and securing data reliability through post-action data recording.

Enhances on-site productivity and stability by analyzing and learning from collected data, and predicts key management indicators and equipment management.

Introducing 12 Key Modules

Comprehensive management of the creation, modification, and disposal of master data in the production process.

Management of production planning, work orders, performance/yield, detailed processes, and manufacturing history.

Collection and monitoring of CCP data, deviation situations, inspection items, and other quality management aspects.

Managing customer communications including receiving customer orders and sharing production schedules.

Real-time management of incoming/outgoing goods, raw materials/semi-finished/finished product inventory, and work-in-progress management.

Management of manufacturing equipment lists/histories, analysis and prediction of predictive maintenance data.

Management of shipping vehicle routes and schedules, overall status, and loading management.

Real-time monitoring of data related to management indicators, enabling monitoring of the manufacturing site.

Management of labels for production and shipping, PPT format label design and management.

Management of user UIs by role and process. Simplification of design and data linkage.

Collection of production, process, equipment, and quality data; analysis/learning modules; prediction and pattern analysis.

Management of interfaces for connecting various applications and services.

The Key to Cost Reduction, Real-Time Monitoring!

Food and beverage manufacturing is highly influenced by factors

like temperature, freshness, shelf life, and maturity of

ingredients such as sauces and finished products.

Seasonal products? Sales products? Shipment products? Set

products? Promotional products? Complicated distribution

channels can be managed in a smart manufacturing environment

using IoT and cloud technologies.

Inventory checking and traceability enable cost savings and

production efficiency at the same time!

Applying in these business areas is

even more effective

Working hard but sales are not satisfying? If your business

scale has grown but so have your losses?

Adopt proven

system know-how in various business fields like food and

beverage product manufacturing, meal kit manufacturing,

catering, etc.

Leaking costs, wasted ingredients, lost

products, return processing, increasing labor costs, and more –

operato chef takes care of it all.

A central hub for recipes, menus & data. Accessible groupwide.

Plan production, generate BOMs & monitor execution.

Order what you need, when you need it. Nothing more.